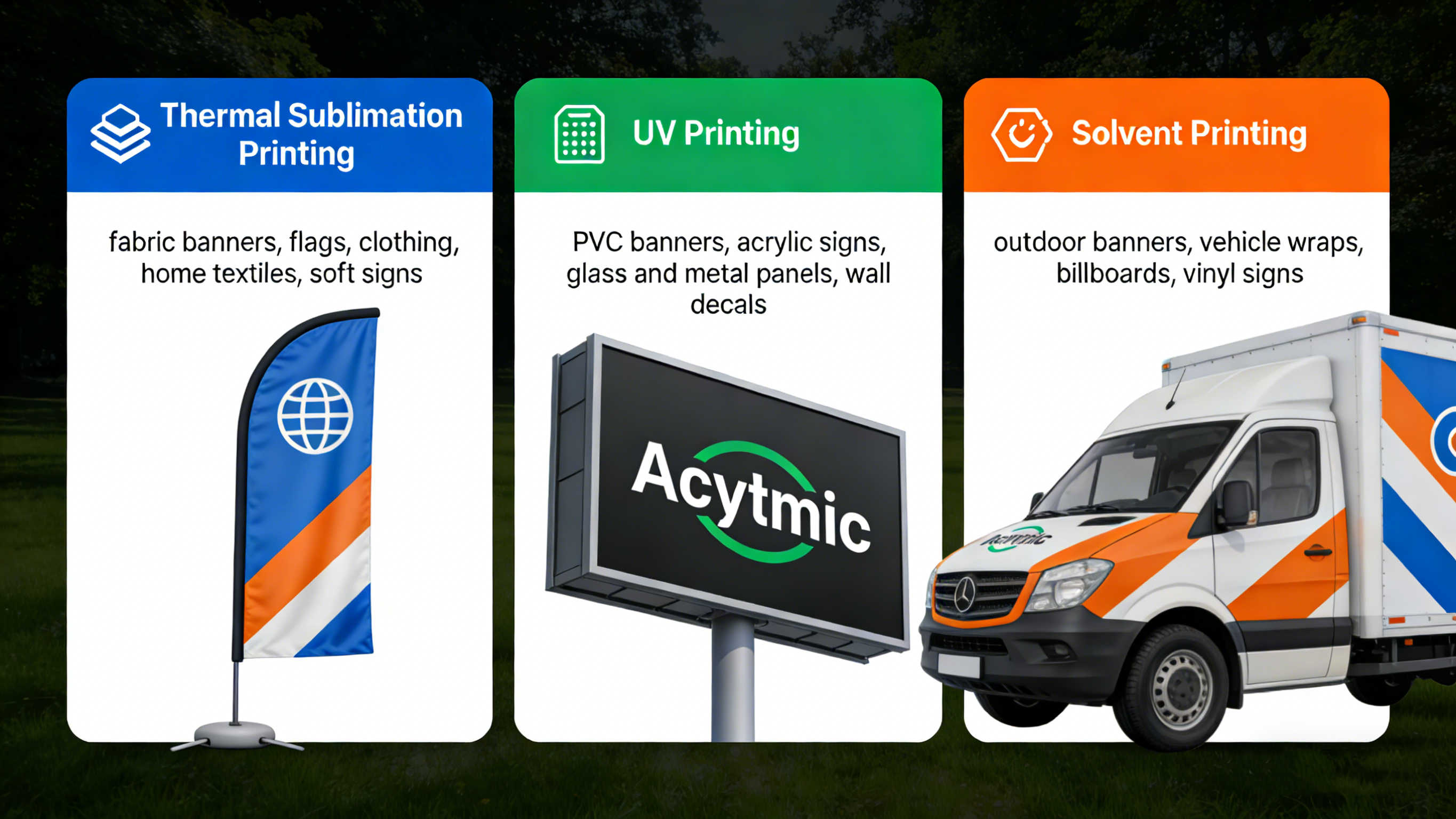

Digital printing technologies have transformed the signage, textile, and advertising industries. Among the most widely used printing methods are dye sublimation printing, UV printing, and solvent printing. Each method has unique characteristics, ink systems, and material compatibility.

This guide explains the differences, applications, and buying considerations for these three printing technologies.

Digital printing technologies use an inkjet printer to apply ink directly onto substrates. Unlike traditional screen printing, digital printing does not require plates, enabling faster production and customization.

Common digital printing methods include:

Dye sublimation printing uses sublimation papers and transfer paper to transfer ink onto polyester fabrics or coated substrates.

The printing process includes:

This method does not require a traditional curing process because the ink becomes part of the material.

UV printers use UV ink that is instantly cured using ultraviolet light. The ink sits on the surface and hardens through instant curing.

The printing process includes:

Solvent printers use solvent-based inks that penetrate PVC and coated media. Eco solvent printing uses based inks with lower VOC emissions and is more environmentally friendly.

The printing process includes:

| Feature | Dye Sublimation Printing | UV Printing | Solvent Printing |

|---|---|---|---|

| Ink Type | Sublimation inks | UV ink | Solvent / eco solvent inks |

| Curing | Heat press transfer | Instant curing with UV light | Air drying / curing process |

| Surface Feel | Soft, embedded in fabric | Raised ink layer | Slightly penetrated surface |

| Materials | Polyester, polymer-coated | Wide range (rigid & flexible) | PVC, vinyl, coated media |

| Outdoor Durability | Moderate | High | High |

| Environmental Impact | Low | Moderate | Eco solvent is more environmentally friendly |

Different printing methods work with specific substrates. Polyester fabrics require sublimation, while PVC banners work best with solvent or UV printing.

Outdoor signage requires UV and weather resistance, while indoor displays may prioritize visual quality and texture.

Sublimation is efficient for textiles, UV offers premium quality, and solvent printing provides a cost-effective solution for large outdoor graphics.

Eco solvent printing and sublimation printing are considered more environmentally friendly compared to traditional solvent systems.

Sublimation printing embeds ink into polyester fibers using heat, while UV printing cures ink on the surface using ultraviolet light.

Yes, UV printers can print on coated fabrics, but dye sublimation is preferred for soft textiles.

Solvent printing is mainly used for PVC and vinyl materials, not for polyester textiles used in sublimation.

Yes, sublimation printers use sublimation papers or transfer paper before heat pressing the design onto fabric.

Sublimation printing is suitable for fabric banners, UV printing for premium displays, and solvent printing for outdoor vinyl banners.

Dye sublimation printing, UV printing, and solvent printing each serve different market needs. Sublimation is widely used in textile production, UV printing offers fast instant curing and broad material compatibility, and solvent printing remains a popular choice for outdoor signage.

Understanding these printing technologies helps buyers choose the right method based on material, durability, cost, and application requirements.