Polyester fabrics are widely used in digital printing, apparel, home textiles, and industrial applications. Among the most common types are knit polyester and woven polyester fabric. Buyers often compare these two materials to understand their structure, performance, and best use cases. This guide explains the differences between knit polyester and woven polyester fabric, their applications, and how to choose the right option for your business.

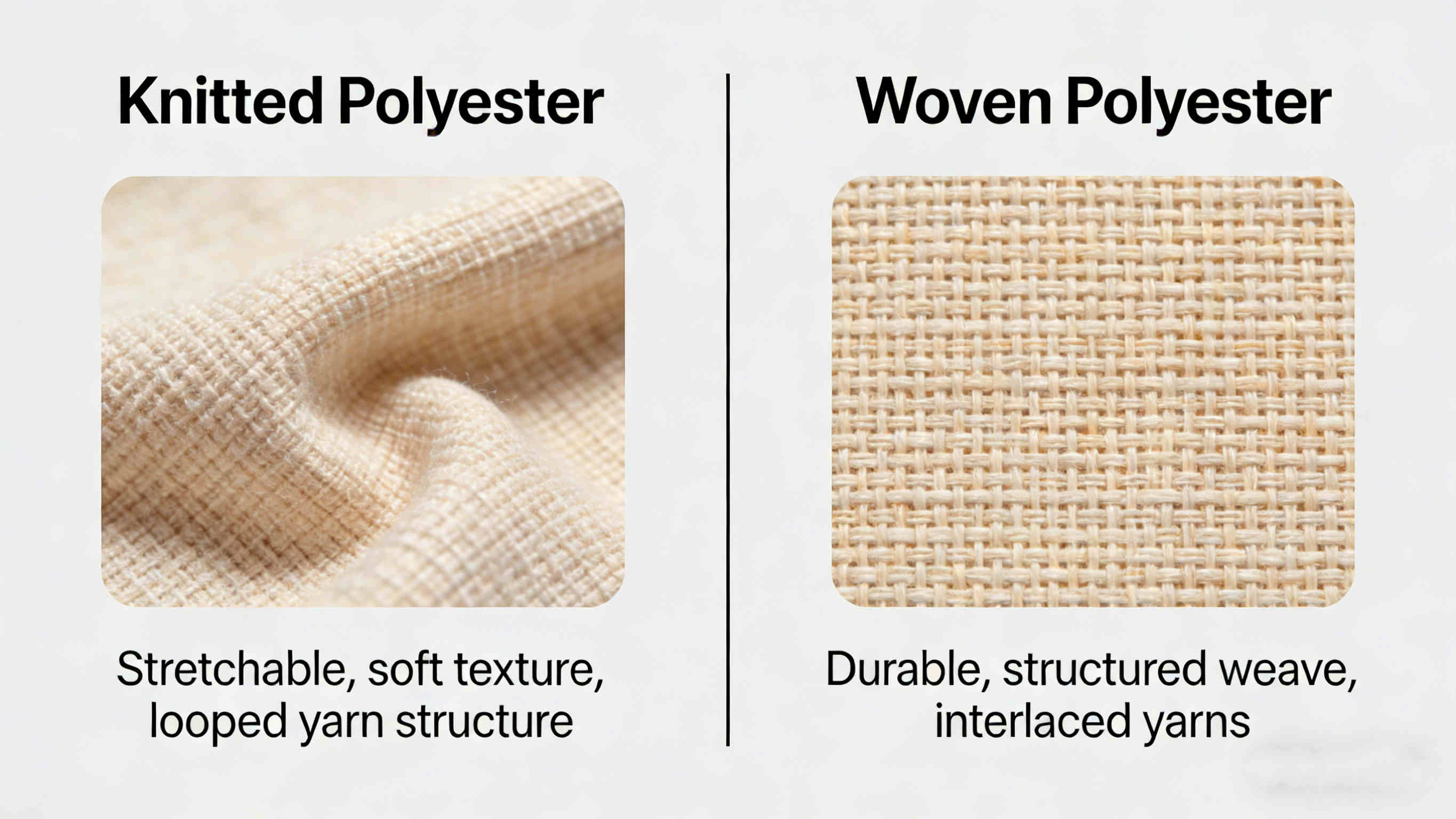

Knit polyester is a textile made using knitting techniques, where yarns are interlooped to form a flexible structure. This construction method produces fabrics that are soft, stretchy, and lightweight.

Knit polyester is commonly used in fabric banners, apparel, sportswear, and soft signage because it drapes well and offers good elasticity.

Woven Polyester Fabric is produced by weaving yarns in perpendicular directions (warp and weft). This method creates a stable and structured textile with higher dimensional stability compared to knitted fabrics.

Woven polyester fabrics are widely used in banners, curtains, upholstery, industrial textiles, and technical applications.

Knit polyester has natural elasticity, making it suitable for applications requiring flexibility.

Woven polyester fabric has limited stretch, making it ideal for structured applications.

Both knit and woven polyester can be used for dye sublimation and digital printing. Knit fabrics provide smooth surfaces for vibrant colors, while woven polyester fabrics offer sharp detail and stable dimensions during printing.

Woven polyester fabric generally has higher tensile strength and tear resistance. Knit polyester is durable but more flexible and less rigid.

Knit polyester is lightweight and foldable, making it easy to transport.

Woven polyester fabric is heavier and more stable, suitable for long-term installations.

| Feature | Knit Polyester | Woven Polyester Fabric |

|---|---|---|

| Structure | Interlooped yarns | Warp and weft interlaced |

| Stretch | High | Low |

| Dimensional Stability | Medium | High |

| Printability | Excellent | Excellent |

| Durability | Medium to High | High |

| Typical Use | Soft signage, apparel | Curtains, banners, industrial textiles |

Knit polyester is made by looping yarns and offers flexibility, while woven polyester fabric is made by interlacing yarns and provides higher stability and strength.

Both knit and woven polyester fabrics are suitable for digital printing. Knit polyester is commonly used for fabric banners, while woven polyester fabric is used for structured signage and textiles.

Yes, woven polyester fabric generally has higher tensile strength and dimensional stability than knit polyester.

Knit polyester can be used outdoors with proper coatings and finishing, but woven polyester fabric is often preferred for long-term outdoor applications.

Costs vary depending on GSM, structure, and finishing. Knit polyester is often used for lightweight applications, while woven polyester fabric may have higher material costs due to its structure and durability.

Knit polyester and woven polyester fabric are two important categories of polyester textiles used in printing, signage, apparel, and industrial applications. Knit polyester offers flexibility and lightweight handling, while woven polyester fabric provides strength and stability. Choosing the right fabric depends on the application, performance requirements, and budget considerations.