Sublimation printing is a popular and innovative technique used to create vibrant, durable, and high-quality prints on fabric. But when it comes to choosing the right fabric for sublimation, not all textiles are created equal. Understanding the characteristics of different fabrics, the sublimation process, and the materials best suited for this printing method will help you achieve the best results. In this blog, we will explore the best fabrics for sublimation printing, why synthetic fibers work better than natural ones, and how to achieve high-quality prints using the right fabric.

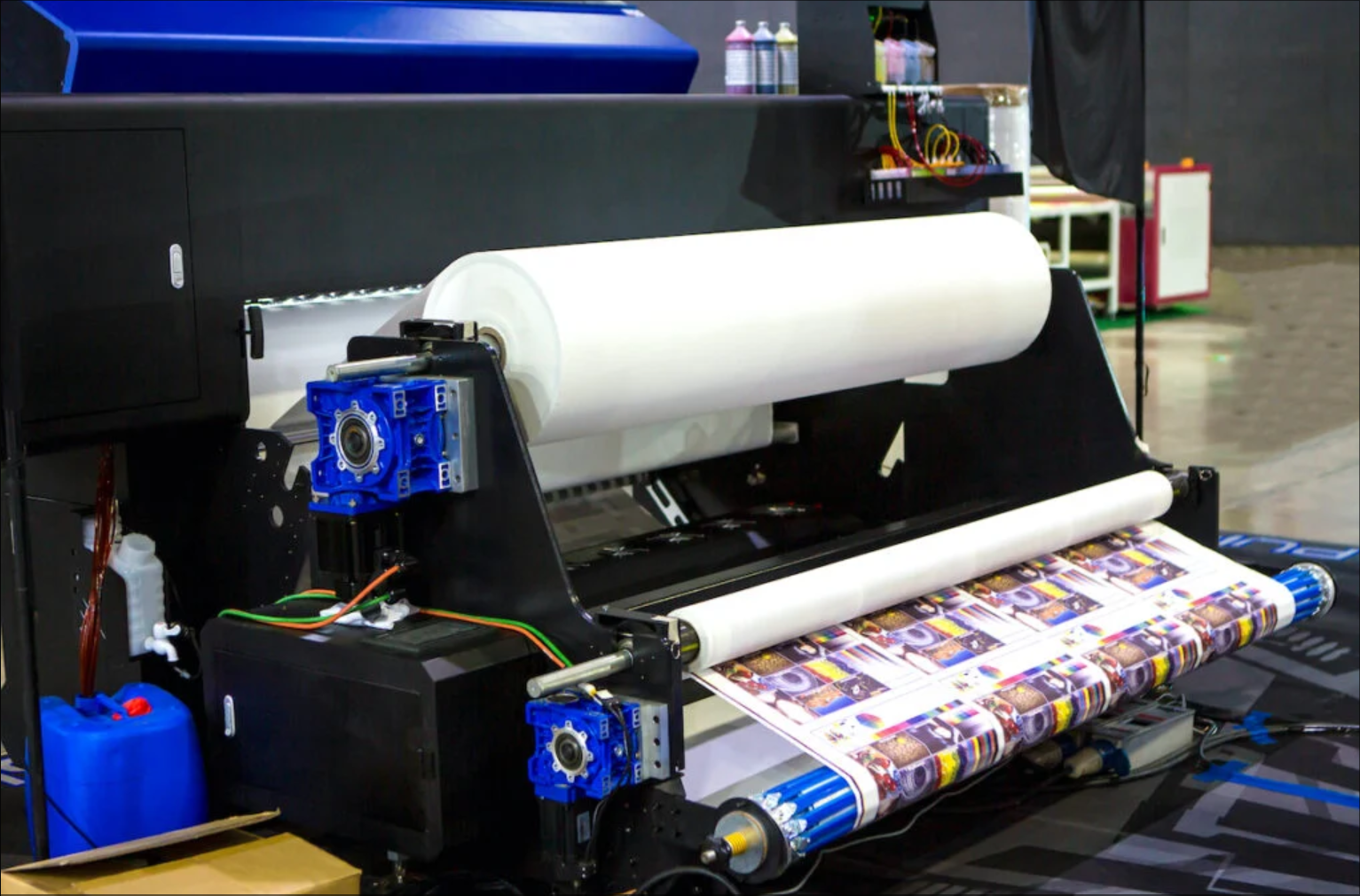

Before we dive into the fabrics, let's first understand what sublimation printing is. Sublimation is a heat transfer process where dyes are heated to their gaseous state and then bonded with the fibers of the fabric. This process allows the ink to permeate the material, creating permanent and vibrant designs. Unlike traditional printing methods where ink sits on top of the fabric, sublimation ink becomes part of the fabric, resulting in prints that won't crack or fade over time.

The best fabrics for sublimation printing are those made from synthetic fibers, specifically 100% polyester. Polyester fabrics are ideal because they allow the sublimation ink to bond seamlessly with the fibers, ensuring high-quality, long-lasting prints. Polyester blends, such as a polyester and cotton blend, can also be used, but the results may not be as vivid or durable as on 100% polyester fabric.

Polyester fabrics are made from synthetic fibers, which are well-suited to the sublimation process because they are more receptive to the heat and pressure involved in the transfer. When the sublimation process takes place, the ink enters the polyester fibers in a gaseous state, bonding to the fabric at a molecular level. This means the prints are incredibly durable and will not peel or fade over time.

In contrast, natural fibers, like cotton or silk, do not bond with sublimation inks as effectively. Since natural fibers do not open up as readily to gas during the sublimation process, the print quality on these fabrics is usually less vibrant and can fade much more quickly.

Now that we know that polyester is the go-to fabric for sublimation, let's take a look at the specific types of fabrics that work well with this printing method:

Sublimation printing relies heavily on heat and pressure. The heat press machine plays a crucial role in transferring the sublimation ink from the transfer paper to the fabric. As the heat presses the paper against the fabric, the sublimation inks transform into a gaseous state, where they bond directly with the polyester fibers. This process ensures that the print quality is sharp, vibrant, and permanent.

The main advantage of dye sublimation textiles is the ability to print highly durable and long-lasting designs. Unlike other printing methods, sublimation printing produces quality prints that will not peel, crack, or fade over time, even after repeated washing.

To achieve the best results in sublimation printing, it's important to consider the following:

When it comes to sublimation printing, 100% polyester is the best fabric choice. The combination of polyester’s ability to accept sublimation inks and its durability makes it the ideal material for creating high-quality, long-lasting prints. Whether you’re designing custom sublimated fabric for apparel, banners, or home decor, the right fabric will ensure vibrant colors, detailed prints, and a product that lasts.

For the best results, always choose polyester fabrics or polyester blends, and ensure that they are compatible with the sublimation process. Whether you're creating custom sublimated fabrics or printing a sublimate polyester shirt, understanding the nuances of the sublimation process will help you create designs that stand the test of time.