When it comes to customizing fabric, two of the most popular methods are sublimation printing and heat transfer. Both processes are widely used in the textile industry for creating vibrant, high-quality prints on various fabric types. However, each method has its own unique characteristics, benefits, and ideal applications. In this blog post, we’ll dive into the key differences between sublimation printing and heat transfer, particularly focusing on their use with 100% polyester fabrics and other materials, and how they impact the final product.

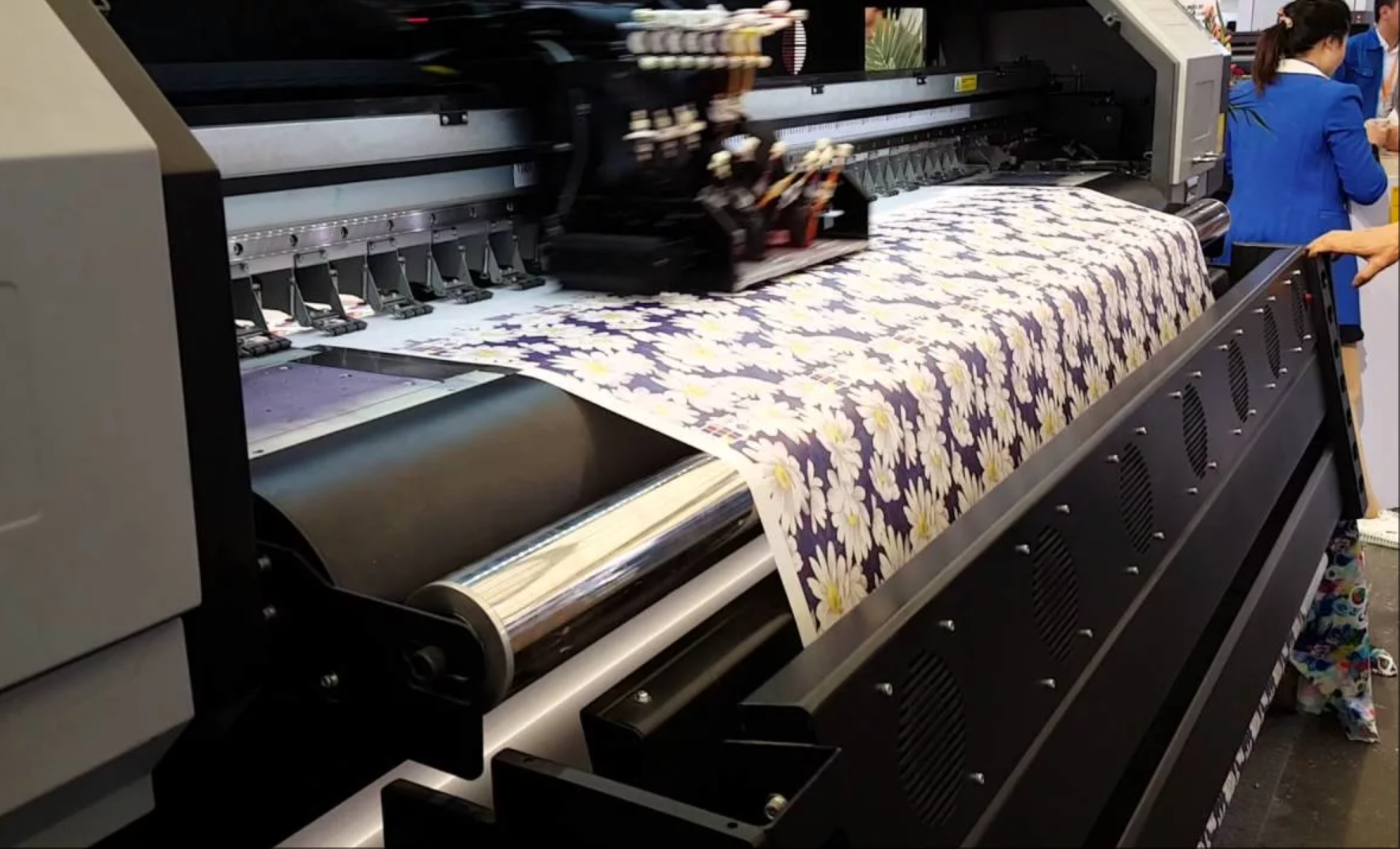

Sublimation printing is a digital printing technique that allows you to transfer dye sublimation inks onto fabrics. The sublimation process involves turning the dye into gas under heat and pressure, allowing it to penetrate the fabric fibers and bond with them. This results in vibrant, long-lasting, and highly detailed prints that become an integral part of the fabric itself.

When you print on sublimation blank fabric, especially 100% polyester or polymer-coated materials, the ink becomes part of the fabric, which means the design won't fade, peel, or crack over time. It’s particularly effective for creating colorful designs, detailed logos, and full-color images. This method works best on sublimation fabrics, as polyester fibers have the perfect properties to absorb the ink.

Sublimation works best with fabrics like woven flag fabric, oxford fabric, and warp-knit fabric, which are ideal for banners, flags, and sportswear. Satin fabrics, with their smooth texture, also produce stunning sublimation results, making them ideal for promotional products and apparel.

Heat transfer printing, on the other hand, involves transferring a design onto fabric using heat and pressure. In this method, the design is printed onto a special transfer paper, and then the paper is applied to the fabric using a heat press. The heat and pressure cause the design to bond with the fabric's surface, creating a transfer that can be peeled away after cooling.

Heat transfer printing works well on a variety of fabrics, including cotton and polyester. However, when it comes to sublimation printing on polyester fabric, heat transfer might not be as effective or permanent. The prints created with heat transfer are often on the surface of the fabric, making them more susceptible to wear and tear over time, particularly with frequent washing.

However, when using sublimation inks, heat transfer methods can result in less vibrant prints compared to sublimation printing, especially on 100% polyester. The print quality and durability are generally inferior to those achieved by sublimation.

| Aspect | Sublimation Printing | Heat Transfer Printing |

|---|---|---|

| Fabric Type | Best on 100% polyester and polymer-coated fabrics. | Works on various fabrics like polyester, cotton, and blends. |

| Ink Type | Uses sublimation inks that bond with the fibers. | Uses heat transfer inks on a transfer paper. |

| Durability | Prints are permanent and resistant to fading. | Prints can peel, crack, or fade over time. |

| Color Quality | Vibrant and high-definition prints. | Colors can be less vibrant compared to sublimation. |

| Touch | Soft to the touch; no surface feel. | Prints may feel slightly raised or rigid. |

| Production Speed | Longer setup but good for larger runs. | Faster for small runs or custom prints. |

| Best for | Full-color designs on sublimation fabrics like woven flag fabric, oxford fabric, and satin. | Ideal for small quantities or custom apparel, such as t-shirts and hoodies. |

| Process | Requires heat and pressure to turn dye into gas and bond with fabric. | Requires heat and pressure to transfer the design onto fabric. |

When it comes to sublimation printing, 100% polyester fabrics are your best bet. The material’s high polyester content allows the sublimation inks to bond effectively, resulting in high-quality prints that won’t fade or crack. Warp-knit fabrics, often used for sportswear and activewear, also work well for sublimation because of their stretch and smooth texture.

For heat transfer printing, a wider range of fabrics can be used, including interlined black fabric, cotton, and polyester-cotton blends. Oxford fabric is another fabric that is commonly used in heat transfer printing due to its durability and easy handling.

While both sublimation printing and heat transfer printing are effective methods for customizing fabric, sublimation printing offers superior quality and durability when used on 100% polyester fabrics and other materials designed for sublimation. Heat transfer printing, though versatile and faster for smaller runs, doesn’t provide the same long-lasting results as sublimation, particularly on polyester fabrics.

If you’re looking for high-quality prints that last, sublimation printing is the way to go. But if you’re working with a variety of fabrics or need to produce small quantities quickly, heat transfer printing may be the better option for your project.

Whether you're designing sublimation banners, woven flags, or custom apparel, understanding the difference between these two printing methods will help you make the right choice for your fabric and design needs.